Highlights and Benefits

- Using automated recipe-based perfusion to harvest stem cells.

- No need for oxygen sparging, and the probes are already calibrated.

- Materials with USP Class VI certification

- Personalized therapy for the adhesion of cells

- Processing allogenic stem cell cultures for cell and gene therapy requires special consideration.

- Single-use formats that are simple to handle and validate

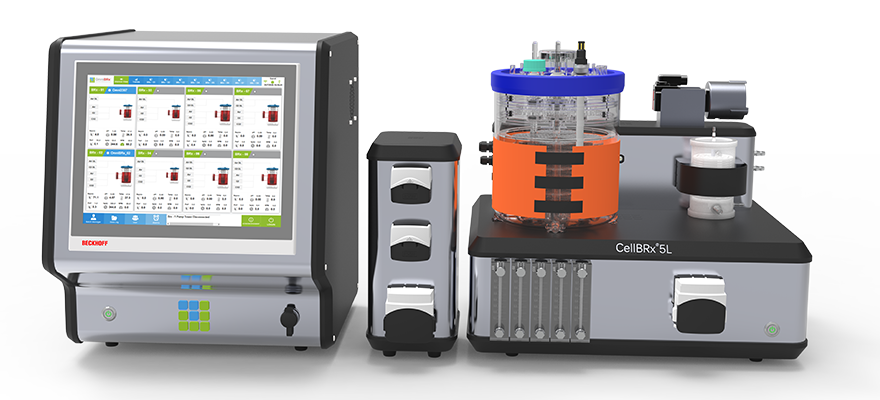

CellBRx® 5L bioreactor systems are more suitable for large-scale Allogenic Stem cell production. The surface area of the 5L scale bioreactor vessel, which is equivalent to the utilization of 16 No. Cell Factories (CF-10) is roughly 10 m2. Without harsh treatments or shear forces, this 5L single-use culture tank can support the growth and synthesis of about 330 billion stem cells and automated recovery of these stem cells for harvest. The CellBRx® 5L bioreactor system excels in bioprocessing, offering a versatile platform for the scalable production of stem cells. By supplying the essential biomass or cells that will later go through downstream processing to extract, purify, and formulate the final product, upstream bioprocessing lays the groundwork for a successful biomanufacturing process. In the industries of biotechnology, pharmaceuticals, and regenerative medicine, it is essential.

FEATURES

- Integrated mixing system for low shear stress and media circulation that distributes evenly.

- Precisely treated cell carriers that are tailored to different adherent cell cultures.

- Using specialized DBR technology, efficient mixing and uniformity are guaranteed.

- To assure process dependability, a single-use bioreactor is built of stiff plastic that has received USP Class VI and ISO 10993 approval.

- Dynamic beds are available in modular sizes ranging from 1 L to 200L, providing both small- and large-scale unique combinations.

- Closed bioreactor that is entirely single-use from vessel to sensor to reduce the danger of contamination and sterility.

- Monitoring and maintaining control over culture parameters such as pH, DO, temperature, glucose, biomass, and others ensured the repeatability and traceability of cell cultures.

- Engineered to be used in a fully closed system from seeding to harvest.

- Flexibility in processing with simpler procedures, less complexity, and fewer dangers associated with operations (such as cell, seeding, medium exchange, and harvest)

Equivalent units of conventional technologies (Surface area comparison)

Equivalent units of conventional technologies (Surface area comparison)

The Comparable Units Of Standard Technology (Comparison Of Surface Areas)

The CellBRx® 5L system is a pilot-sized bioreactor that can hold 5L capacity culture containers (which are easily accessible) for pilot-scale studies and small-scale manufacture of biologics, including recombinant medicines and vaccines.

Cost advantage (% reduction of upstream produciton cost)

For more information on CellBRx® 5L system please contact us